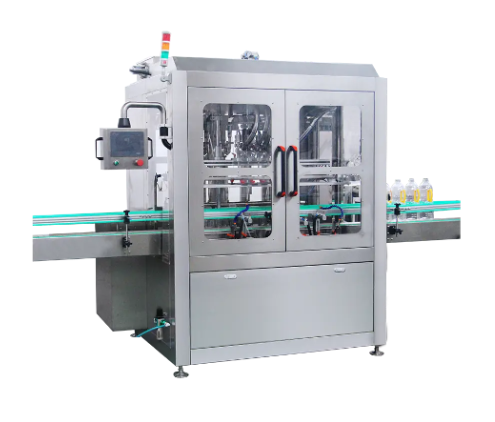

For industries where powder compaction is essential in some fields, such as the drug, cosmetic, or chemical industry; an appropriate technology, in this case, is the powder press machine. The equipment provides controlled and automatic pressing, essential for the tight quality control of powdered compaction into various forms with high precision and repeatability. Why a Powder Press Machine Can Change Your Production

Precise and consistent

Powder press machine is unmatched in qualified accuracy to compact powders. Compression accuracies of +/- 0.5% or tighter are offered by these machines, based on application requirements and machine settings. This accuracy keeps every product at an even weight, density, and volume so that every consumer can expect the same kind of performance from the product.

Provides Production at a Faster Rate

After all them positoning themselves exactly, the powder press machines provide the same speed. With this facility, they can process large batch sizes very fast, usually pressing a few thousand per hour. This efficiency is necessary to survive in the market and to meet the production timelines without any compromise in the quality.

Versatility in Product Design

These are highly adaptable powder press machines which can press powders of various types and granule sizes into different shapes/formats. This versatility means a broad variety of products can be produced by the same machine, ranging from tablets and capsules in pharmaceuticals to compact powders in cosmetics. These options provide flexibility to fine-tune press parameters, such as pressure and fill depth, allowing clients to develop individually optimized part solutions for different markets.

Less Waste, Higher Yield

Benefits: Reducing product waste(One of the most important characteristics of a powder press machine) The machines also ensure that each unit uses the exact amount of raw material by perfectly measuring and compacting the powder, Bottlecrusher stated. This reduction in waist also leads to an increment in yield which eventually makes the production process a less expensive and more sustainable one.

Enhanced Product Quality

By providing uniformity and precision, powder press machines greatly improve the quality of the end product. Controlled compaction ensures there are no trapped air pockets, and products are compacted to the correct size for the best performance every time. This means having the rugged, reliable products that also are up to code.

Integration and Automation Relationships

Components of the new powder press machines are modern and they allow simple integration into existing production lines as well as into fully automated systems. These are usually provided with improved control systems which makes them an easy to operate and supervise hardware and it avoids the necessity of a much more hence time taking definitive manual control.

Low Maintenance and Long Lasting OPerformance

Powder press machines are built to last many years of production, using only the highest quality parts that give reliability and require very little maintenance. This allows the equipment to be operational for longer periods of time without significant breakdowns, leading to a more dependable, productive production process.

Industry Standards Enforcement

Lastly, The machine is also compliant to meet industry standards to ensure that all products comply with the industry of regulations. These machines offer precision and control of the process resulting in end product that complies with all required specification and quality checks that are crucial in industries under stringent regulatory requirements,

Investing in a powder press machine for your line, only to comeuppance in terms of precision, efficiency and quality. In a market where high-quality products have to be produced at a rapid pace, using a powder press machine is a wise decision that can meet all your needs of pressing every kind of powder and waste reduction.