How Is a Huge Satellite Dish Constructed?

Constructing a huge satellite dish is an engineering feat that involves meticulous planning, precision engineering, and collaboration across multiple disciplines. These giant structures are crucial for advanced communications, astronomical research, and global broadcasting. Here's a detailed look at the step-by-step process involved in building one of these colossal antennas.

Initial Design and Engineering

Designing a huge satellite dish begins with a detailed engineering process. Engineers must determine the optimal size and shape of the dish to meet specific signal reception requirements. This involves complex calculations to ensure the dish can support high-frequency bandwidths and withstand environmental factors like wind, rain, and extreme temperatures. The design phase includes creating detailed blueprints and 3D models, often using advanced computer-aided design (CAD) software.

Material Selection

Selecting the right materials is critical for the construction of a satellite dish. Materials need to be durable yet lightweight to withstand the rigors of outdoor environments and to maintain structural integrity over time. Common materials used include high-grade steel for the supporting structure and a mesh or solid surface made of aluminum or specialized composites for the dish itself. These materials are chosen for their ability to reflect radio waves effectively and resist corrosion.

Foundation and Support Structure

Constructing the foundation is the next critical step. A huge satellite dish requires a strong and stable foundation to support its massive weight and operational stresses. This often involves pouring extensive concrete foundations, which may be reinforced with steel to provide additional stability. The support structure, which includes the pedestal and possibly a rotating mount, is then assembled. This structure must be precisely leveled to ensure that the dish can be accurately pointed towards specific areas in the sky, crucial for signal capture.

Assembly of the Dish

The dish itself is assembled either on-site or in segments at a factory. Large dishes are often constructed in segments that are transported to the site and then pieced together. This modular approach helps in managing the sheer size and makes transportation feasible. Precision is paramount during assembly to ensure that all segments align perfectly, forming a parabolic shape necessary for focusing incoming signals.

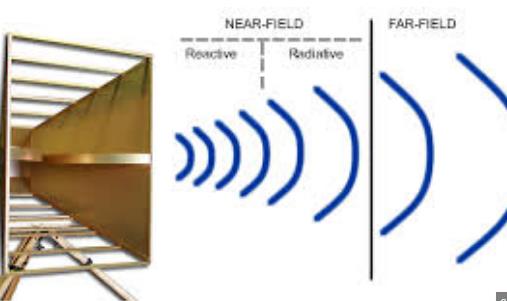

Installation of Reflective Surface

Installing the reflective surface is a delicate process. The surface of the dish must be smooth and contoured accurately to focus signals effectively. For mesh dishes, this involves attaching the mesh tightly over the frame to avoid any sagging that could distort signal reception. Solid dishes might use aluminum panels that are bolted onto the frame, requiring careful alignment to maintain the precise shape of the dish.

Calibration and Testing

Once the dish is assembled, it undergoes rigorous testing and calibration. This includes adjusting the dish's orientation and fine-tuning its position to maximize signal reception. Engineers use a range of instruments to measure the dish’s ability to receive and focus signals, ensuring it operates at optimal parameters. This phase might also involve testing the dish under different environmental conditions to simulate real-world use.

Constructing a huge satellite dish is a complex process that requires high levels of precision and expertise. Each step, from design to calibration, plays a crucial role in ensuring that the dish performs as expected, providing vital communications and data transmission capabilities that have become essential in our interconnected world.